Let’s tackle a persistent myth. The myth is that the US Army does not like autoloader systems for tanks. Proponents can point to the M60 having a human loader and the Abrams having a human loader, and then cite all of the nice things about having a fourth man in the tank when it comes time to post guards or do labor-intensive maintenance like fixing/swapping tracks, and ipso facto, the US Army loves human loaders. Clearly autoloaders are only for godless commie scum and cheese-eating surrender monkeys!

Of course, when we actually bother to look into the matter, those meddlesome facts get in the way of our carefully crafted myth. The US Army actually loves autoloaders. Let us examine the evidence.

Exhibit A is the MBT-70. This ill-fated project was a joint effort between the Americans and the Germans. It would end up being doomed by cost overruns and an inability to come to agreements on a number of key systems, including the gun and engine. However, one thing the Germans and Americans did agree on was that it should use an autoloader. Yes, that’s right, the wondertank of the 1970s embraced new ideas like an adjustable, hydropneumatic suspension and a fancy mechanical loader, just like the T-64. Since I like arguments supported by sources, and we’re busting myths here, one might consult a good source like Hunnicutt’s Abrams volume for details of the MBT-70’s design.

Exhibit B is the early design sketches of what would become the M1 Abrams. Again, we’re looking at Hunnicutt’s excellent work on the subject. The US Army originally wanted an autoloader for the Abrams, but then had it deleted to try to help sell Congress on the idea that the notional Abrams was economized and not a high-risk, gold-plated project like the MBT-70.

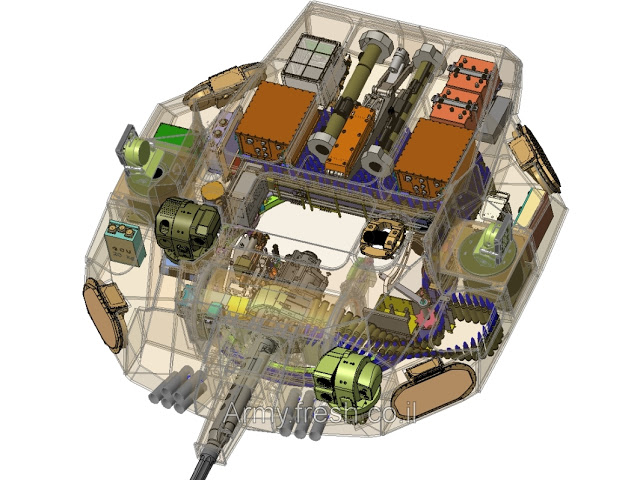

Exhibit C is the Abrams follow-on plans. Autoloaders galore. TTB had an autoloader. CATTB had an autoloader. The Abrams Block III proposals all had autoloaders. Want to upgun? That needs an autoloader. Want to isolate the ammo and the crew and reduce the turret profile? Gonna need an autoloader. Want to try to pretend you’re keeping the weight down as you add armor to deal with the relentless improvement of tank guns? Autoloader.

So there you have it. The US Army actually likes autoloaders.